September 18, 2018 12:00 pm |

September 18, 2018 12:00 pm |

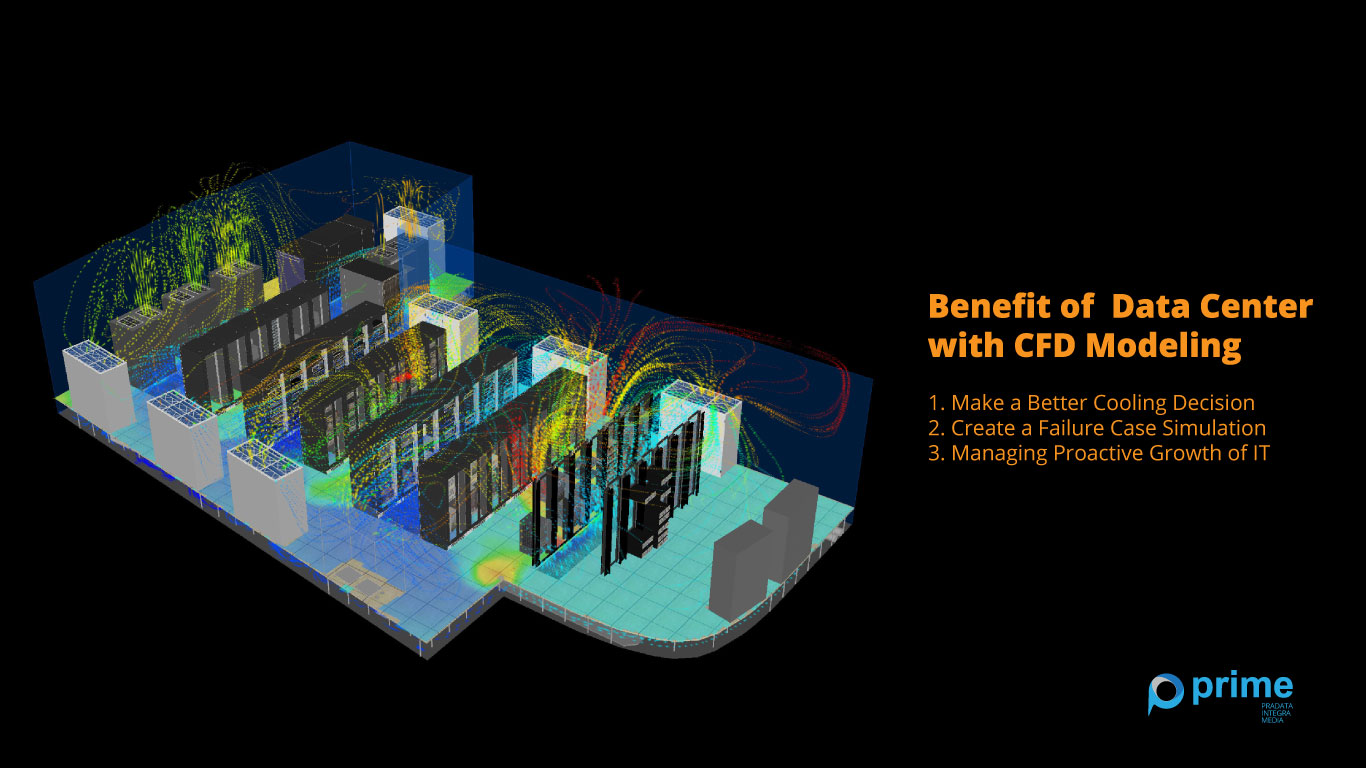

Data Center Managers will be greatly helped if they can predict the future. With that, they can minimize the occurrence of downtime, wasted energy, and errors in data center design. Future predictions in the era of technology like now are no longer impossible. CFD analysis (computational fluid dynamics) and modeling (air flow simulation) will be able to present it for you.

Before changes in the data center actually occur, this software can help you evaluate options, weigh the causes and consequences of changing data centers and make decisions through simulations. This device can operate your data center as efficiently and less risk as possible. Over the years CFD modeling has been applied in various fields of life ranging from biomedical, aerospace, film graphics as well as game development. Now, CFD modeling has been able to develop its use as a capable design and maintenance tool for data centers. Predictive modeling, how-if scenarios and capacity planning can be made with detailed 2D and 3D CFD analysis.

For information such as the status of your current data center and predictions of what might happen in the future, this software can be relied on. Thus, long before the equipment is installed, the data center can be designed in advance so that it can be operated based on specific needs and characteristics.

Data center technicians can visualize and provide power and cooling. Meanwhile, IT planners can implement IT systems where power distribution and cooling are available.

By making CFD model part of the data center workflow, users can:

- Streamline capital expenditure costs and improve the effectiveness of data center designs

- Predict thermal and electrical resistance of each IT device

- Perform failure scenarios to ensure resilience can be maintained

- Compare various vendor options

- Predict, plan, identify , and prevent from hotspots

- Increasing capacity that can be used without reducing the active time

- Validating thermal solutions

Here are a few examples of what you can do with powerful CFD modeling software.

- Make a Better Cooling Decision

How do you decide which AC option is best for your space? Without having to move equipment or devices, you can use CFD modeling to test various approaches in terms of impact on availability, capacity and efficiency. With this software, you can:

- Analyze the effectiveness of cooling shelves and aisles

- Find areas that receive more cold air than needed

- Identification of potential hotspots at the equipment site does not receive sufficient air flow

- The right area where cold air mixes with hot air, reduces Cooling effectiveness

- The air flow model under raised floor

- illustrates the effect of CRAC failure on air flow temperatures and the inlet rack

- Thermal Management Engineeringto improve energy efficiency.

- Create a Failure Case Simulation

Want to know what will happen if you change your data center layout, or exchange one equipment with another? With CFD modeling software you can run a full failure case simulation. Try to simulate changes, if the system fails, see how failure impacts the data center environment in terms of availability, capacity and efficiency.

You can also compare the consequences of using different vendor equipment in your data center. For example, if you try to decide between three heat retaining solutions, try them all through CFD modeling first to see how each impacts your data center.

- Managing Proactive Growth of IT

Along with business growth and managed data, data centers also need additional devices and equipment. IT equipment has changed over the years, and the impact on air flow can also be different. This means that, new equipment does not necessarily match the previous position and layout of the device.

The design and interaction of these components can be determined by the data center capacity and the threat of downtime. Not after a series of equipment has been purchased and placed new, there is a shortage of air flow. This will be ineffective and inefficient. By simulating a change plan first, you find the best design configuration before the device and equipment are placed. See firsthand how the equipment layout, the location of the refrigeration unit, the hot and cold retaining aisles, under-floor barriers and different vendor equipment affect the data center air flow and temperature distribution.

PRIME DCS through a Virtual Simulation technical simulation using CFD modeling (Computing Fluid Dynamics) of 6SigmaDCX and 6SigmaET from Future Facilities to explain the impact of air flow and thermal management on data centers and energy efficiency to customers who want to manage their data centers. With this simulation engineering, PRIME DCS has helped many customers bridge IT and facilities.

Learn more about Data Center Solutions, CFD Modeling Services and Consultation by the Expert Team of PRIME DCS to maximize the availability, capacity and efficiency of your data center.

Tags: 3d modeling data center, 6SigmaDCX, 6SigmaET, CFD consultant, CFD modeling, data center simulation, Future Facilities